Aircraft Rivet Size Chart - The Zenith 750 is on display at AirVenture, assembled with blind grooves. This simple design feature made it a good candidate for One Week Wonder last year. Zenith uses a special system to install their blind rivets, so be sure to read the instructions and get the right tools before starting your project.

Rivets have long been popular in aircraft construction and still exist today. They provide a great way to bond aluminum sheets together smoothly and firmly. Therefore, it is not uncommon for many manufactured experimental / amateur aircraft to rely on these rigid connectors. Although rigid rivets remain the standard for most aircraft designs, aircraft grade blind rivets, sometimes called pull rivets or POP rivets, are emerging after they can save a lot of time to build and assemble their aircraft. They. A quick tour of vendors at the latest AirVenture featuring blind rivets used in devices by CubCrafters, Murphy, RANS, Van's, Zenith and more. In addition to its use in basic aircraft structures, blind ovens have many non-structural applications that are of interest to builders, including ensuring the sealing of the wings to the engine wings.

Aircraft Rivet Size Chart

The blind seam gets its name from the fact that it can be installed in a socket into a place inaccessible or visible to the installer. In other words, it can be installed in a "blind" socket. On the other hand, a normal rigid aircraft trailer must be mounted so that access to the rear is essential for proper installation.

Stay Cool Adult Tee

There are many blind rivets on the market, so buyers must be careful to find the right rivet for the job. Some of these are aircraft quality, but most are not. So some of them can be used for structural work but others certainly not. However, there are many places where unstructured blind rivets can work well.

As with solid seams, the shape and composition of the seams make a huge difference. With blind rivets, the composition of the rivet stem or mandrel is also an important factor. For example, aluminum rivets can come with aluminum or steel stems. Those with iron rods are usually stronger.

On the subject of clover stems, the ability of clover to hold its stems under conditions of high loads and strong vibrations separates aircraft rivets from their commercial cousins. The seam loses much of its strength if the stem falls off. Many low-cost commercial blinds will not hold their original with confidence under adverse conditions. This is why they are not normally used for something on a plane that holds them together or keeps them together. It works.

Cherry Aerospace, Avex, Avdel, Emhart, POP and others create a wide selection of blind rivets in a variety of materials for commercial and aircraft applications. They range from N rivets, non-structured commercial rivets, to Cherry MS, CherryMAX, and CherryLOCK structural rivets as well as similar rivets from other manufacturers. Between commercial blinds and aircraft, we have Q rivets that are not strong enough to replace AD rivets of the same size but with structural strength and high quality characteristics. N and Q rivets can be easily installed with any commercial blind rivet tool, but CherryMAX and CherryLOCK rivets are best installed with special tools designed only for stronger rivets. In squeezing CherryMAX rivets can be installed using a standard riveter, but it is not under best practice.

The Structural Sketch Of Slug Rivet Assembly

Q rivets are available in steel, aluminum, stainless steel and Monel. Stainless steel Q rivets will work well for assembling stainless steel firewalls instead of using Monel driven rivets. Monel blind rivets also work well with stainless steel or titanium. Most tool manufacturers will allow the next larger Q seam to be replaced for AD seam (1/8-inch Q seam for AN470AD-3 seam), but this should be verified on a case-by-case basis. In all cases, when one type of seam is replaced by another, it is best to run an aircraft designer to make sure they agree to leave their design.

If we need a 1/8-inch blind rivet to replace the 1/8-inch AD rivet, we have another possibility - the CherryMAX rivet. The CherryMAX 1/8-inch aluminum seam has a shear strength of 664 pounds and a tensile strength of 285 pounds. This makes it stronger to cut than 1/8-in. AD rivet but weaker tension. Since most rivets are loaded in the cut, using CherryMAX as a replacement may not be an issue. However, it is likely that this is not a problem and will not be a problem, so it is a good idea to consult your aircraft manufacturer or designer before making such a replacement. One of the advantages of CherryMAX rivets is that they are standard size and 1/64-inch oversize for broken holes.

Just for clarity, do not replace blind rivets for different materials for strength. Although it is certain that the Q rivet made of stainless steel or Monel sheet will combine or exceed the strength of the rivet AD of the same size, such replacement should be made only after consultation with the designer. Fly and after considering the possibility of different placement. Concerns of metal rust.

There are cost issues with different types of rivets. AD gears in normal size usually cost less than two cents each if you buy a quarter pound or more. Q rivets with a diameter of 1/8-inch will cost about 18 cents each, about ten times more. CherryLOCK or CherryMAX rivets will run for about 75 cents each. Q rivets seem to be a good choice for firewalls or unstructured applications such as machine wings.

Nutsert Drill Size Chart

Some aircraft builders who are designed to use blind rivets may decide to use AD rigid rivets instead. Some builders Murphy Moose and Super Rebel did this in the hope of making their aircraft more robust or at least more durable. Whether they achieve or not their goal is difficult to say. If the aircraft is designed with blind rivets, it should make sense to use those rivets in accordance with best practice. Are there any good cases to be made against using the AD chopsticks instead of the specified chopsticks? I do not think so, unless using HR rivets will be more work. One special note about this - if you are building an ELSA aircraft designed with a cover like the RV-12, then you can not replace the AD rivets without the written permission of the equipment manufacturer. If you do, you will lose your ability to register it as an ELSA and will instead be subject to a trial / volunteer rule.

Let us take a look at the different types of rivets available for amateur aircraft builders and see where they can be used in accordance with best practices.

Below is an array of N rivets. They are available in aluminum with aluminum or steel legs and in steel with steel legs. They also come with universal water flow heads or large heads for various unstructured applications.

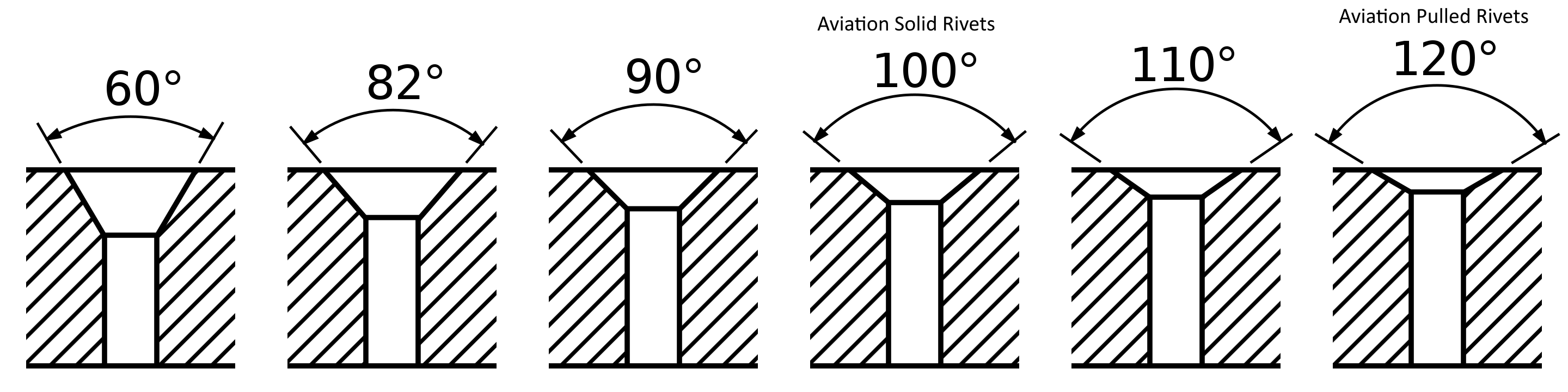

N rivets are non-structural commercial blind rivets manufactured by companies such as Avdel and others. The rated strength of these rivets is low because it can not maintain their stems reliably, leaving only the hollow sections to withstand shear loads and stresses. They should only be used for objects that do not contain essential elements. N-rivets with large flanges are popular for attaching wing seals to aluminum engine shields or for attaching interior decorative elements. The emerging heads listed in the table are almost identical to the universal heads in structural rivets. The jet head version of these rivets only comes with a 120-degree stand, not the 100-degree used in aviation.

Rivet Nut/rivnut Flat Head Metric Rivet Nut Threaded Inserts Nutsert Countersunk Head Splied M5 M6 M8 Riveting Nut Made In China

These are Q aluminum rivets. They come with a universal head and a 120 degree water head. They are not available with the 100-degree warheads commonly used in aircraft construction. However, they are available in other materials such as stainless steel, sheet metal and Monel.

Q rivets now manufactured by Avdel are sometimes called poor CherryMAX rivets. However, it gives them too much credit. They are not structural rivets in any broad sense, although they can sometimes be used to replace smaller rivets after AD with the approval of the aircraft designer. The Q seam is not the same size as the straight AD seam by any means. Like N rivets Q rivets come with a 120 degree counting angle. Q rivets have a significant advantage over N rivets in that they maintain their originality with confidence. This makes them an intermediate step between real structural rivets and non-structural commercial rivets. These rivets are available in aluminum, stainless steel, plated steel and Monel. N and Q rivets are easy to install with most commercial rivet guns.

Cherry MS rivets are the lowest grade blind rivets manufactured to military standards. They deserve the CherryMAX title of Poor Man Q

Aircraft rivet specifications, aircraft rivet gun kit, aircraft rivet kit, aircraft rivet removal tool, aircraft rivet set, aircraft rivet tools, best aircraft rivet gun, aircraft rivet drill size chart, aircraft rivet sizes, aircraft rivet gun, aircraft brake rivet tool, aircraft rivet squeezer

0 Comments